Build your experience

Pricing

A two day course, second day running from 12-3, where we cover spinning of a previously dyed fleece which has been dried, is $345.

Spinning

Spinning lessons are taught either on my handmade Louet-inspired single treadle wheel, or my Ashford Country Spinner 2.

If you have a finished project in mind to knit, crochet, or weave, feel free to bring along a pattern and we can make sure that the yarn is suitable.

Depending on your experience level, in your class we can cover the basics of spinning, setting up your wheel, spinning worsted vs woolen, spinning singles and plyed yarn, and lockspinning and tailspinning. Sometimes a certain type of yarn suits a specific way of spinning, and we can discuss this too. There are many different types of yarns dotted around my studio, so you can decide if there’s a new technique you’d like to try or if a certain type of yarn catches your eye.

Dyeing

For me, dyeing is the process of taking a beautiful fleece and personalizing it. It becomes art, yet this is still just one more step along the journey of turning your fiber into the finished piece, whatever that may be.

I trained with Natalie Redding from Namaste Farms for over a year to become a certified Master Dyer and teacher and her techniques are inspiring.

In a dye lesson, which is taught either one-on-one or with your small group, we will cover the basics of dyeing, the chemistry, and the tenets of the Redding Method philosophy. We will dye your fiber in the colorway of your choice, either kettle dyeing or oven dyeing.

If you would prefer to learn to dye finished yarn instead of loose fiber, we can move the dye lesson around to accommodate that. If you would like to learn to dye milled yarn, please let me know in advance, along with your weight preference, and I will order some in for you.

The cost of the lesson covers the shampoo, dyes and tuition.

Beyond this initial lesson, further dye classes are available to cover other techniques, troubleshooting and colorways.

Sheep and wool

Whether you have a favorite kind of wool you just can’t get enough of, or you want to try something different, I’ve got you covered here.

On the farm, you will find Jacob, Navajo Churro, Icelandic, Icelandic x Border Leicester, Jacob x Churro, Icelandic x Jacob, Border Leicester, mini Cheviot and Tunis sheep.

Each wool has its own unique characteristics, and a purpose for which it is just perfect. Try one, try them all. Put a face to the fiber, bury your hands in the fleece, and see which one appeals to you!

Fiber processing

Once you have chosen your fleece, we will barn skirt it as we shear, and I’ll explain my process for shearing and bagging, along with the various parts of the fleece and how they differ. Then, we will lay the whole fleece out and skirt again, leaving us with the prime areas, which will become our yarn.

Often, fleeces will benefit from being tumbled, to remove second cuts, some vm and dust.

If you are planning on dyeing your fleece, it is likely that we will split your experience into two days, as the fleece will need time to dry. In this case, the carding process will come after the dyeing.

Carding is where we brush the fibers into some kind of order in preparation for spinning; a either a batt made on the drum carder, or rolags made on the hand carders. Some fibers can be spun from the cloud with minimal preparation, and we can discuss how this affects spinning techniques and look at some sample yarns.

At this stage we can also blend your fleece with some other kind of natural fiber such as wool, mohair or silk, or with some sparkle, such as angelina or firestar. I’m a huge believer in letting a fiber speak for itself, and not processing the character out of it, which is why I avoid milled fibers wherever possible, but I also believe there’s few things in the world can’t be made even better with a little sparkle.

Angora goats and mohair

Mohair is the holy grail of fibers, in my opinion. There is nothing that takes dye the way quality mohair does, and the luster, handle and shine are breathtaking.

Mohair is the holy grail of fibers, in my opinion. There is nothing that takes dye the way quality mohair does, and the luster, handle and shine are breathtaking.

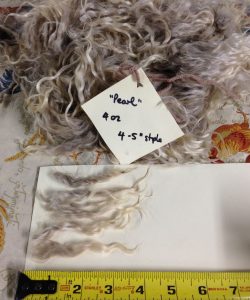

Angoras were the first fiber animals to join the flock, back in 2010. I still have my first three, Pearl, SuzieQ and Tipp. Tipp is now an old, stinky buck with some antisocial habits, but I love him anyway.

These three are the foundation of my mohair herd, and were later joined by Cilla, my first MyGora (Pygmy x Angora). My herd is now usually between 25-30 goats, all carefully selected for the quality of their fiber, their parasite resistance and their general hardiness.

Angora goats are easy to handle, easy to shear and their fiber is so versatile. Longer locks are sometimes used for doll hair, such as the ones used by Lunart Dolls by Desi.

When brushed out and prepared, the locks become works of art. These locks below were prepared by a wonderfully talented lady who purchased fiber from SuzieQ.

Mohair can either be carded, or spun directly from the lock, known as ‘lockspinning’. The image on the left shows kid mohair dyed and lockspun with minimal preparation, while the picture on the right shows punis, or mini-rolags, which is moahir that was washed, dyed and carded on hand carders before being rolled ready for spinning.

There’s so many wonderful ways to experiment with mohair – I’d love to help you find the way that fuels your imagination!

Alpacas

The huacaya alpacas on the farm come in every natural color under the sun, including white, ivory, tan, mid brown, chocolate brown, and true black. In suri, I have three whites.

While alpaca fiber does take dye well, there’s something about a natural blend of the colors that I just love.

Alpaca blends well with wool, to give it some ‘memory’, with silk for a cannot-be-matched softness, or it is lovely to spin on its own.

Occasionally there will be cria fleeces available, or a two-year fleece that I have allowed to grow for extra staple length. If you are interested in one of these, let me know.